Product Description

GTI Owners - This will only fit cars equipped with the Performance Package brakes. If you are unsure about which brakes your car has, contact us and we'll be happy to help!

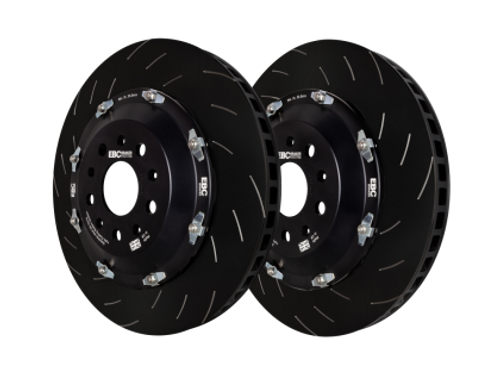

EBC Automotive brake rotors are made from G3000 spec cast iron and full specifications and properties can be seen here! Runout figures above this will lead to vibration after 3000 to 4000 miles due to what we call disc thickness variation which is not a warranty condition. So you see this is no cheap import brake disc. These brake discs have the highest integrity and product quality on the aftermarket. An OE quality replacement disc, made of the finest grade iron and a perfect replacement disc for any car.

Every EBC rotor is runout inspected on this machine. Even when manufactured on state of the art precision machines, not even ONE single disc escapes this process guaranteeing perfect disc alignment. If during install you notice runout on your car it will surely be due to a chassis alignment that happens on one in seven cars, usually cased by nudging a kerb or hitting a pothole in the road earlier in driving the vehicle.

New GEN 3 Silver Grey Rotors and the Logic Behind It

In the past few years, EBC Brakes has enhanced its rotor production facilities, now over 80% of our rotor castings are produced in Europe and 100% of machining for sport rotors is done in either the UK or the USA.

EBC switched in early 2023 to a new silver grey Geomet style coating color, the photograph opposite from the AutoSport show a few years ago, shows what our rotors looked like before and the photo below shows the new product

The Reason For The Switch

- Silver color leaves the rotor hat or hub silver in appearance after bedding in – more likely to match a vehicle’s original rotor colors, so the front and back of the car look similar if you have only changed one axle

- The new silver finish has far higher corrosion resistance to the former black etch paint (thermic black versions)

- Painting is now done as a part of the rotor production process in the actual casting plant. This facility is more environmentally friendly, and air quality controlled and it also means the rotor castings are coated right after machining and washing leaving no time for surface corrosion to set in which happens minutes after a rotor is washed and left as naked iron

We call these… GEN 3