Product Description

APR's 370x34mm 2-piece 6-piston Big Brake Kit (BBK) is an ultra-high-end solution for maximum stopping power. Each feature-packed solution is specifically tailored to your vehicle and provides exceptional stopping-power in a wide operating range from daily driving to professional racing. Because of this, the system provides the correct brake bias and integrate perfectly with the ABS and stability systems which is critical under emergency braking situations. This upgrade handily out-brake, out-last, and out-perform massive non-vehicle application specific OEM swap kits, and rivals much more expensive top-tier systems. Whereas most systems on the market either make heavy sacrifices to either look fancy, cut weight, or cut costs, the APR system is designed to simply brake better, last longer, and stand the test of time!

Features:

- 6-Piston next-generation weight-savings billet calipers with stainless steel pistons

- 2-Piece 370x34mm semi-floating discs with 72 curved directional cooling vanes

- High-performance street pads (Pre-loaded, standard replacement size)

- Braided stainless steel brake lines

- Billet caliper mounting brackets

- All necessary install hardware

- Premium components, machining, and QC throughout

- Low noise, vibration, and harshness

- Maximum Temperature Recording systems for choosing appropriate pads and fluids

- Comprehensive fitment and bed-in instructions

- Stops quicker, last longer, and is more consistent than stock

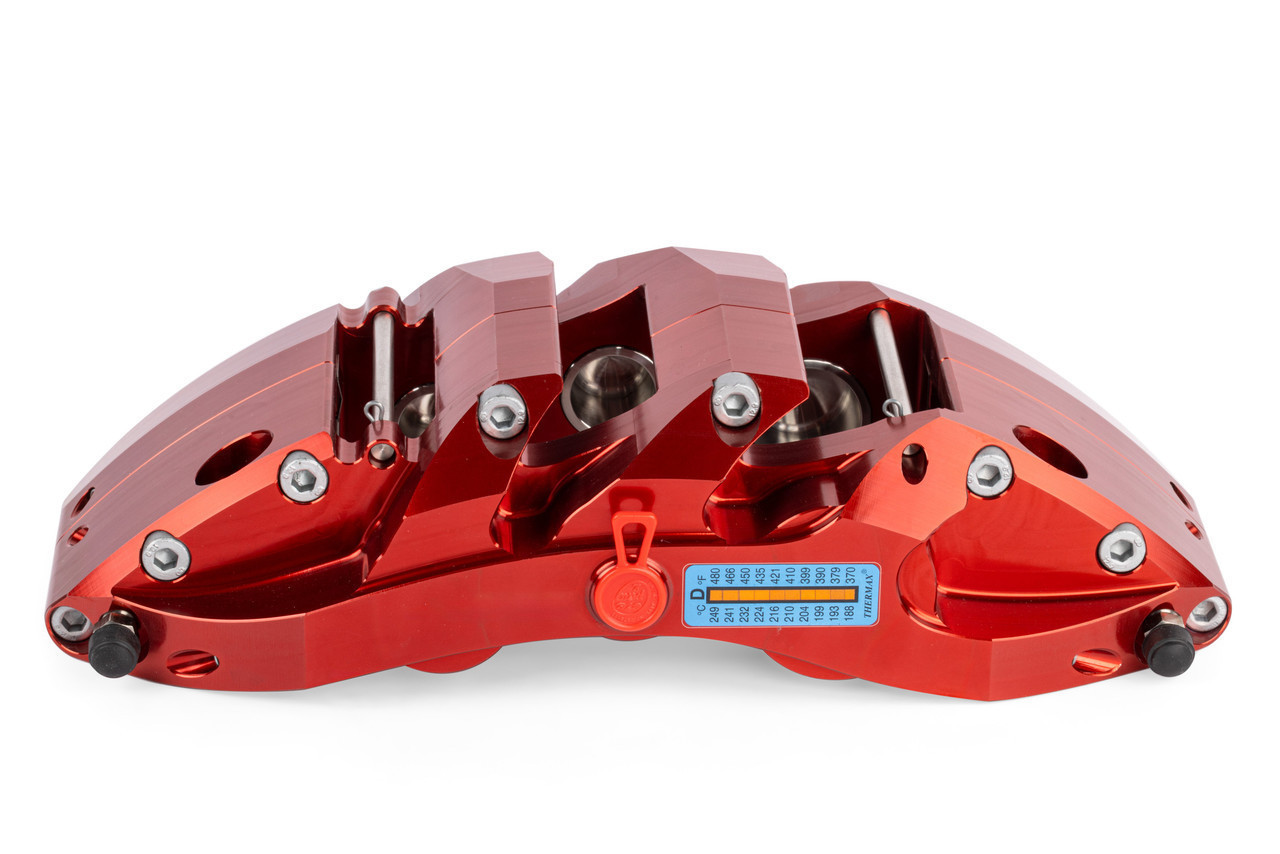

Caliper Design

Our next-generation calipers were designed using cutting-edge ‘Generative Design’ software. Unlike traditional FEA, the Generative Design approach places the specified material only where it needed for strength, rigidity, and safety. This new design is 15% lighter and 20% more rigid than the calipers they have replaced. The extreme rigidity directly translated into an exceptional brake pedal feel, while also enhancing caliper cooling and peak operating temperature.Caliper Pistons

Each piston uses 6 stainless steel pistons made from a special grade that has twice the tensile strength as lower grade 304SS. This is vastly superior to other materials, such as aluminum. They transfer heat slower than lesser materials and reduce the chances of boiling brake fluid, or degradation seal life.Caliper Cross-Bolts

To increase rigidity, the calipers use a 2-piece bolted design. This is superior in rigidity to mono-block calipers, especially those made from lower quality aluminum. Location of the bolts was FEA analyzed to provide optimum rigidity and enter from the inboard size to remain hidden from view. Each bolt is European sourced and coated with a silver zinc flake coating which provides exceptional corrosion resistance.Caliper Internal Fluid Crossovers

To increase reliability of the system, the fluid crossover tubes are built within the billet caliper. Bleed screws are positioned inboard. This prevents possible damage when removing and installing wheels, especially under the demands of racing, increases clearance, and improves the aesthetics of the system.Caliper Construction

Each system is machined from a solid piece of high-grade aerospace aluminum billet which results in a finished product that exhibits exceptional levels of strength and rigidity with an impressive rigidity to overall size ratio. The slim profile of the calipers reduces un-sprung weight and aids with wheel clearance.Caliper Finish and Logo

Our BBK is available in either a Red anodize (type-2) or a Dark Grey hard anodize (type-3). The anodize dyes used for our Red finish have been carefully selected to offer the maximum UV and temperature resistance to ensure long-term color retention. Dark Grey hard anodize is more durable, and recommended for advanced track or race use. The APR logos use applied using advanced laser technology that is not suspectable to heat, fluid, or solvent like paint on or inlay logos found on other systems.Caliper Maximum Temperature Recording (MTR) System

The system provides a permanent record of the maximum operating temperature reached by the caliper. This gives our pro and racing users valuable data when selecting braking fluid.Caliper Hardware

All other components, including pad retaining pins, bleed screws, and pad abutments, are manufactured from stainless steel for the highest levels of corrosion resistance.Caliper Mounting Brackets

Each set is machined from billet aircraft grade aluminum alloy, FEA enhanced for strength and rigidity and (type-3) hard anodized. Stainless steel threaded inserts are used on the radial mount bolts which provides increased strength over aluminum threads.Brake Lines

Each line features an extruded Teflon inner lining that is highly resistant to the aggressive chemical properties of modern brake fluids, as well as being able to handle far higher temperatures than rubber. The Teflon lining is covered by 32 strands of tightly woven stainless steel braid that acts as the muscle of the hose, providing incredible resistance to expansion under pressure. Our stainless braid is covered with a polymeric outer layer that prevents dirt from getting between the stainless braid and the Teflon inner lining. The end fittings on our hoses are all machined from grade-304 stainless steel as opposed to the plated, mild steel fittings used by many of our competitors. The resulting hose assemblies offer the best possible pedal feel, matched to excellent durability and corrosion resistance.Brake Pads

The included pads are designed for everyday use on the street and light track use and are a proprietary compound made specifically to our standards. The pads are in a standard size allowing users to choose one of our racing pads, or any number of other pads on the market.Brake Disc Rings

APR uses massive 370x34mm brake disk rings for maximum stopping power. They are cast from a proprietary high-carbon iron alloy which exhibits excellent durability and stability under high thermal loads common in track conditions. Each disc features 72 curved, directional cooling banes which significantly increases cooling vane surface and airflow compared to factory designs, vastly improving cooling. The slot pattern provides even heat distribution across the disc surface while delivering a strong initial bite and excellent release characteristics while still maintaining a low noise, vibration, and harshness (NVH) rating. Every single disc undergoes a final thickness variation (DTV) and run-measurement to ensure our QC and tolerances are up to 3 times higher than the industry norm!Brake Disc Surface

The brake disc are coated black with a proprietary material that protects the rings from unsightly corrosion in the upswept areas of the disc. After a few braking cycles the initial surface will be wiped away where the pad contacts the disc, but will remain in areas where it’s not touched. Each disc is chemically degreased before this coating is applied to ensure no contaminants can be absorbed into the brake pad.Brake Disc Maximum Temperature Recording (MTR) System

The outer edge of the brake disc includes our MTR system that provides a permanent record of peak operating temperature of the disc. This is vital information when selecting the correct pad compounds for your application.Brake Disc Hats

Machined from a solid piece of light-weight high-grade aluminum alloy, each system undergoes FEA strength and thermal analysis to confirm strength and rigidity under load. The hats are finished in a dark grey, type-3 hard anodize for maximum durability and service life. Each logo is laser etched.Brake Disc Floating System

The semi-float system allows the disc friction ring to expand and contract radially without any restriction as it heats and cools. This significantly reduces stresses within both the disc friction ring and the disc hat and reduces the changes of disc distortion and cracking while still maintaining consistent brake pedal feel. Furthermore NVH (noise, vibration, and harshness) remains slow and quiet during daily driving.TECH RESOURCES